Defined by BS ISO 445 a ‘Pallet’ is a horizontal platform of minimum height, compatible with handling by pallet trucks and or forklift trucks and other appropriate handling equipment. Commonly used as a base for assembling, storing, handling and transporting goods and loads in factories and warehouses.

Pallet accidents are usually caused by:

- Poor design of the pallet

- Unsuitable pallet for the load

- Unsafe stacking

- Use of a damaged pallet

All these accidents can be avoided by developing and following safe working practices. The use of pallet trucks is covered by the Provision & Use of Work Equipment Regulations 1998; they state the equipment must be suitable for purpose as well as meeting maintenance and inspection requirements. The reason for this is to enable smart risk assessing to identify hazards and risks from using and stacking pallets in the workplace.

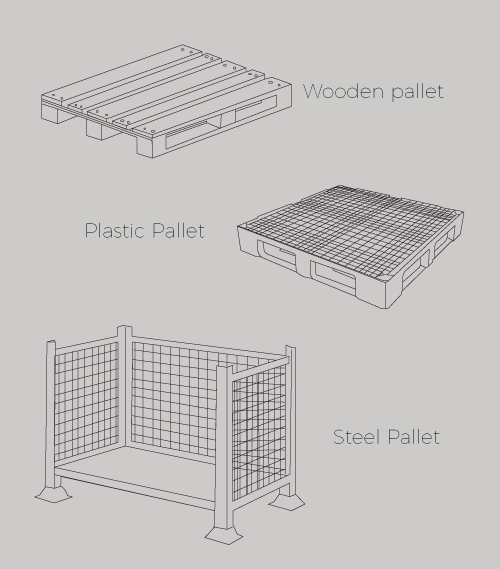

Types of Pallets

- Wooden Pallet

- Plastic Pallet

- Pressed Wood Pallet

- Corrugated Cardboard Pallets

- Metal Pallets

Pallet Considerations

When choosing pallets there are many things that need to be considered. The designers of the pallets consider all the following to ensure suitability for the loads are correct:

Suitability & Design

A pallet designed to transport evenly distributed loads such as cartons of cornflakes or sheet paper will not be suitable to carry concentrated loads such as an electric motor. The design of the pallet is adequate strength for the purpose intended.

Loads

- Type of load (Solid, Liquid, Powder)

- Does the load have corrosive properties?

- Weight and its distribution

- What are the requirements for safe transportation of the load, is additional restraint required?

Movement

Is the pallet to be moved by pallet truck or forklift or another device. What sort of entry is needed to lift each pallet?

Stacking?

The load on the bottom of the pallet and the capacity of each base board is taken into consideration when spreading and stacking the load. Taking this into consideration should ensure that the pallet doesn’t distort, this can occur with various loads for reasons as various as moisture and temperature.

Pallet Management Planning

Stability of the load

Pallets should be loaded and stacked correctly to achieve optimum stability and safety. Loads should be applied gradually unless specifically designed for point loading.

Height of the load

As a rule, the height of the load should not exceed the longest base dimension. To increase the stability of the load, shrink wrapping can minimise the movement of goods on the pallet.

Plastic Pallets

These types of pallets are known to have slippery surfaces, extra measures may be needed to secure the goods during transportation and stacking. ** attention may be required as these are slippery and potentially unstable on the forks of a forklift.

Pallet Use & Maintenance

Pallets should be regularly checked; by the user for damage. Each damaged pallet should be marked, isolated and removed from use for disposal. The frequency of these checks should be before every use of the pallet to ensure they are in a safe and fit working condition.

Disposal pallets are intended for one time use; they are not meant for reuse.

Pallet Inspection

The following lists offer a basic guide for pallet inspection as made by the HSE.

- In four-way perimeter base pallets every base board is fastened at each end with two or more nails that appear to be of correct length and diameter with adequate edge distance.

- The stringer boards are made of quality timber and there aren’t too many knots

- The stringer boards are made of equal thickness

- The deck boards are made of solid timber and not too many knots

- There are no damages bearers or blocks

- No projecting nails or nails pulled through the deck board

- There are no edge splits in any board members

- No loose joints sticking out of the pallet

- The pallet is clean and free from contamination

- No part of the pallet is defective

- The pallet is free from cracking, flaking and or wear

- There are no signs of water absorption, indication by swelling or blistering

- The pallet is not distorted

- The hollow supports are free from debris

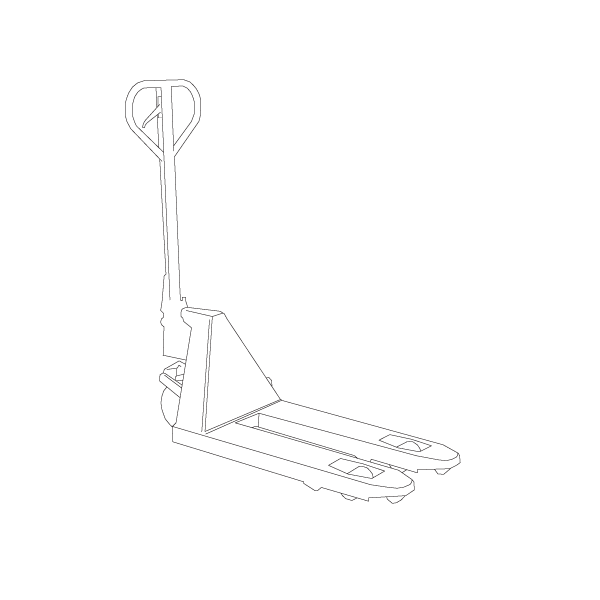

Pallet Truck Safety

It is important that people responsible for the use of the equipment must carry out specific risk assessments.

- Plan the job in advance

- Take care once the equipment is fully loaded, it may be difficult to control or stop

- The action of a pallet truck can cause injury if not used in a controlled and careful way

- Familiarise yourself with the equipment before using it

- PPE: safety boot & gloves must be worn whilst operating

- The equipment is intended for use by a trained individual, please seek advice if you are not trained.

Work Area

- When working in the same route frequently, put up barriers or signs to warn people crossing the routes

- Ensure the work area is clear and safe, that there is no one to cause distraction

- Plan the route so that you do not have to travel on rough or soft ground as equipment wheels will not operate to the best of their ability.

Operators

- Safety boots must be worn whilst using this equipment

Pallet Truck

- Check the pallet truck and the hydraulic operation. If anything is found to be damaged, do not use

- Do not exceed the UDL marked on the equipment

- Never allow anyone to ride on the truck that is designated to only carry materials

- If items are being loaded onto an empty pallet, first check the pallet is in good condition and strong enough for the load

- Load the pallets carefully to ensure every load is secure, you may need to use shrink wrap or ties

- Always pull the pallet truck whenever possible, push it only to get the pallet truck in its final position

Using the Pallet Truck

- Wear safety boots & gloves

- Always load the truck carefully as well as taking the safest route

- Keep the load as low as possible with the weight evenly distributed

- Do not allow the load to overhang

- Always pull the load except for the final position

- When going up a slope, seek assistance

- Stop working when approached

- Do not leave a loaded pallet truck unattended while it is in the raised position. Release the hydraulic pressure whilst lowering the pallet to the floor

- If the equipment does not work correctly, do not repair.