What is PPE?

PPE is an abbreviation for Personal Protective Equipment – in short, equipment that protects the user at work against health and safety risks. Items including in this definition are hard hats, helmets, goggles, harnesses, safety boots and much more.

Although ear protection and respiratory protective equipment have their own specific regulations, they must also be compatible with any other PPE provided.

Regulation Requirements

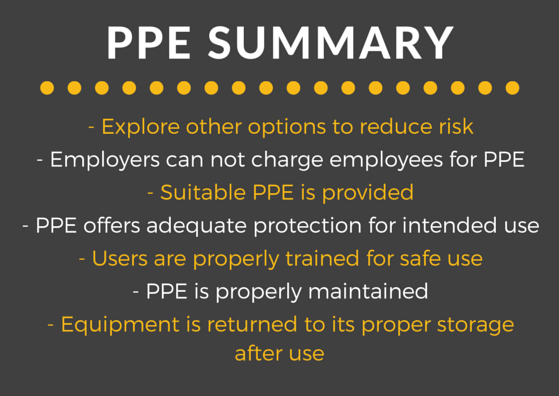

The HSE view Personal Protective Equipment as a last resort. If there are evident risks to health and safety the best cause of action is prevention or other alternatives of control. Of course, in some cases there is no way of avoiding some risks to health and safety, only ways to reduce them and this is where PPE should be supplied. If you supply PPE, here are the requirements:

– Personal Protective Equipment must be properly assessed before use to ensure it is fit for purpose

– PPE must be stored properly

– Personal Protective Equipment needs to be provided with instruction for use

– Equipment must also be used correctly by employees

How to Assess PPE

It is vital to make sure the correct type of PPE is chosen. This can be done by considering all the hazards in the workplace and identifying which equipment would provide adequate protection against them.

Suppliers and manufacturers should be able to tell you specific information about products and specialist advice may be required on what equipment is best suited. A useful source of information on this matter is the British Safety Industry Federation.

It is important to consider several points when assessing suitability:

– Does the PPE protect wearer from risks and take account of the environmental conditions where task is taking place?

– Does using protective equipment create further or increase risks? i.e. will communication be more difficult?

– Is the equipment suited to user? i.e. can it be adjusted to fit?

– If more than one item of PPE is worn are the items compatible?

Selecting and Using PPE

The HSE states that when selecting PPE employers must choose good quality products that are CE marker in accordance to the ‘Personal Protective Equipment Regulations 2002’. When purchasing PPE the wearers must be taken into consideration including size, fit and weight. Users health should also be considered i.e is the equipment heavy or does it affect pre-existing health issues?

When it comes to the use and distribution of PPE it is vital that users are instructed and trained on the correct use of equipment. It is also required that the reasons for use are explained including when to use it and what the limitations are. It is strictly not allowed to give exemptions for jobs that ‘only take a few minutes’. If certain jobs or processes are altered, PPE must be rechecked to ensure it is still appropriate.

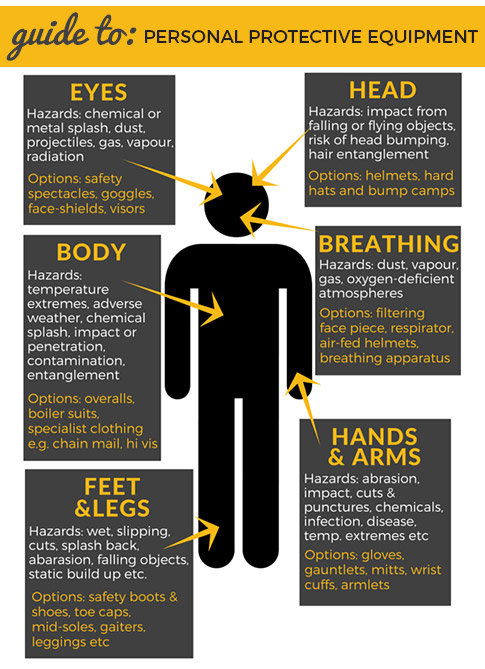

Hazards and Types of PPE

Eyes

Hazards: Radiation, dust, gas and vapour, projectiles, metal or chemical splash

PPE: Safety spectacles, visors, goggles, face-shields

Head

Hazards: Hair entanglement, impact from falling objects, risk of head bumping

PPE: Bump caps, safety helmets, hard hats

Breathing

Hazards: Vapour, dust, gas, oxygen deficient atmospheres

PPE: Breathing apparatus, disposable filtering face piece, half or full face respirators, air-fed helmets

Body

Hazards: Adverse weather, temperature extremes, chemical or metal splash, impact or penetration, contaminated dust, spray from pressure leaks, entanglement of own clothing

PPE: Boiler suits, high visibility clothing, chainmail aprons, over alls

Hands and Arms

Hazards: Abrasion, cuts and punctures, impact, temperature extremes, chemicals, skin infection, disease or contamination, electric shock

PPE: Safety gloves, gauntlets, wrist-cuffs, mitts, armlets

Feet and Legs

Hazards: Slipping, cuts and punctures, falling objects, abrasion, wet, electrostatic build up, chemical and metal splash

PPE: Safety boots and shoes – with protective toe caps, penetration-resistant mid-sole, leggings, spats, gaiters

Training

The importance of training can not be underestimated. Providing Personal Protective Equipment for employees is essential but knowing how and when to use it correctly could mean the difference between life and death. Wearers must be aware of why PPE is needed, when to use, repair or replace it and how to report it if there is a fault. Users must also be aware of the PPE’s limitations. When training and instructing people on how to correctly use the PPE, ensure managers and supervisors are in the training. Although they may not need to use the equipment themselves, they do need to be sure their staff are using it properly.

It is also important that users are wearing protective equipment all the time that they are exposed to the risk and that no exemptions are made. It should be clear where equipment is stored for visitors to use. Regular checks should be carried out on the use of PPE and incidents where it is not being used should be investigated. Reminders such as safety signs and refresher courses are useful. It should be clear where equipment is stored for visitors to use.

Maintenance

• Make sure equipment is well looked after and stored properly when not in use. An example of this may be in a dry, clean space.

• Equipment should be kept in good condition and clean and simple maintenance can be carried out by either the wearer (trained) or specialists. Users must be made aware of who’s responsible for maintenance.

• Replacement parts should be appropriate and match the original.

Certification

Ensure any Personal Protective Equipment purchased is ‘CE’ marked and complies with the requirements of the Personal Protective Equipment Regulations 2002. Equipment that is CE marked meets basic safety requirements. In some cases a CE mark can also mean that the equipment will have been tested and certified by independent bodies.

Other Regulations

The PPE at Work Regulations do not apply to cases where these five sets of regulations require the provision and use of PPE against these hazards. An example of this would be where gloves are used to prevent dangerous chemicals penetrating skin – this would be covered by the Control of Substances Hazardous to Health Regulations 2002. The five regulations as mentioned above include:

– The Control of Noise at Work Regulations 2005

– The Control of Asbestos Regulations 2012

– The Control of Lead at Work Regulations 2002

– The Control of Substances Hazardous to Health Regulations 2002 (as amended)

– The Ionising Radiations Regulations 1999

Important Things to Remember

Here is a useful infographic to help guide you in the right direction when planning PPE:

Thank you for reading, we hope this post has been useful. Please do not hesitate to ask us any questions regarding our Personal Protective Equipment range. We got all our information from the HSE website, here are some useful links to find out more information:

– https://www.hse.gov.uk/toolbox/ppe.htm

– https://www.hse.gov.uk/pubns/ppeindex.htm

– https://www.bsif.co.uk/

Pingback: PPE Resolutions: Start your year off right - Safety Blog